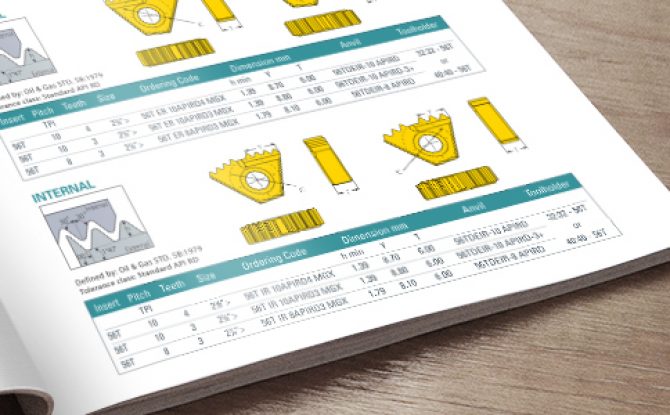

At MACH 2016 Posithread will be unveiling their new range aimed at Sliding Head lathes. The range has evolved from customer demand. Many of Posithread’s customers with sliding head lathes expressed dissatisfaction with the product offering available on the market. The dissatisfaction was not just over the selection of products but also at the high prices demanded.

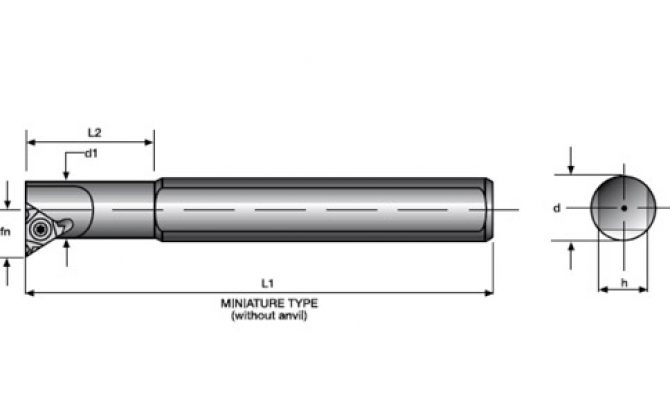

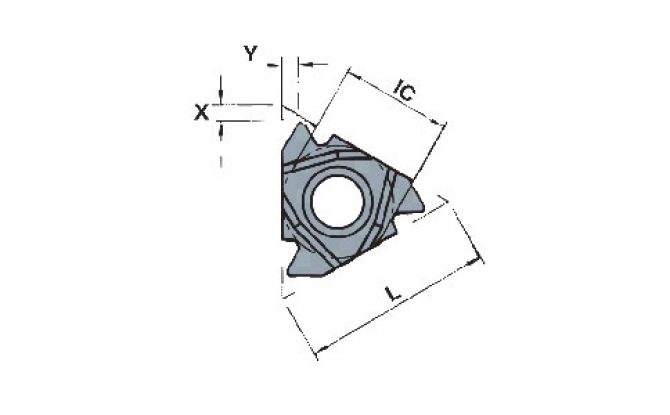

Taking this information; Posithread’s in house design team have come up with a new range aimed primarily at threading but additionally some grooving product.

The tools have been designed with both Citizen and Star machine configurations in mind. With tooling dimensions available to suit the plattens of each type of machine.

The range will also enable Posithread to offer their 3 week special solution turnaround to the Sliding Head Market.

If you’d like to come along and see us, we’ll be in Hall 5, Stand 5294 – we look forward to meeting you!